Introducing The R&D Helium Loop Anorak From Peak Performance

November 20, 2025

A World-First Proof of Concept Showing That Circular Design Can Now Go Beyond Monomaterial

November 20, 2025 /OUTDOOR SPORTSWIRE/ – Born four decades ago in the heart of the Swedish Mountains, Peak Performance is the authority in outdoor adventure clothing, combining the spirit of freeride sports with technical excellence and disruptive design.

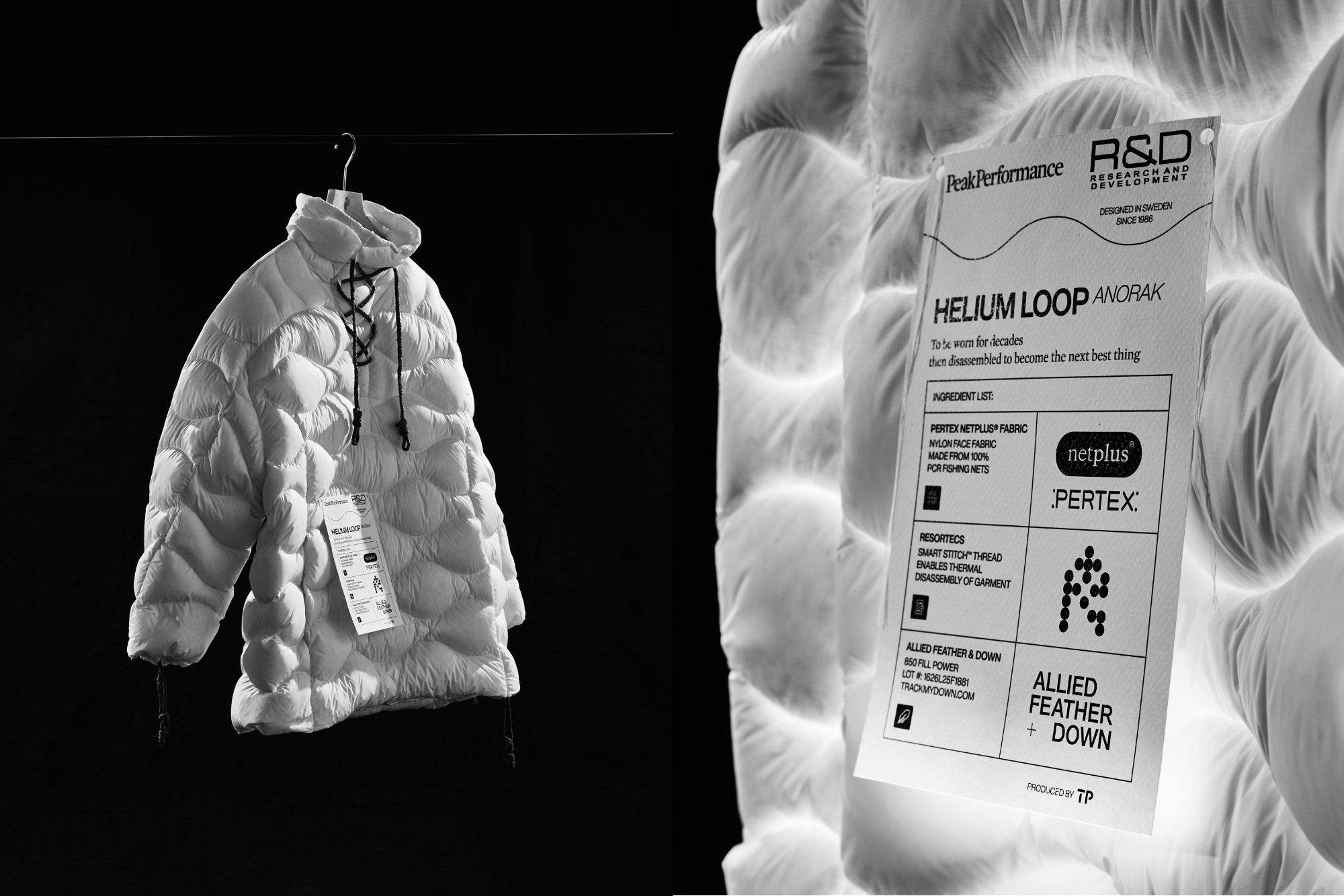

This winter, the brand unveils its latest innovation: the R&D Helium Loop Anorak, a world-first proof of concept that down jackets now have the potential to be fully recycled.

The Anorak concept reimagines product durability, balanced with new methods for end-of-life deconstruction. Until now, products combining multiple materials, such as natural down insulation, have been nearly impossible to recycle due to the complexity of disassembly at the end-of-life. This jacket proves that collaboration can change that. Through close partnership with NetPlus®, ALLIED Feather + Down, Resortecs, and PERTEX, Peak Performance has co-developed an innovative design featuring Resortecs’ Smart Stitch™—a heat-dissolvable thread that enables easy material separation. At the product’s end-of-life, the stitching melts away under controlled conditions, allowing the down plumes and the material membrane to be taken apart and recycled individually.

HELIUM R&D LOOP: THE BREAKDOWN

- Scandinavian design: The Helium Loop Anorak is designed as a mid-weight insulation layer for adventurers. The silhouette fluently speaks the same design language as Peak Performance’s iconic Helium range, from which it takes its baffle quilt pattern.

- Designed with intent, not excess: We stripped it back to what matters. ALLIED down for warmth, PERTEX | NetPlus® for a tough nylon shell made from post-consumer recycled fishing nets, and Resortecs’ Smart Stitch™, a heat-activated thread that lets it all come apart when the time is right. The jacket is free from hardware or trims (e.g, togs, pulls, and zippers) for faster disassembly. Fewer parts. Fewer problems.

- No performance trade-offs: 850-fill RDS down and PERTEX Quantum NetPlus® shell deliver ultralight warmth, durability, and PFAS-free DWR—proving circularity can enhance design, not compromise it.

- No harmful chemicals: PFAS-free DWR treatment provides weather protection without persistent fluorochemicals. No intentional PFAS is used in processing. Undyed prototype eliminates textile dye chemicals entirely. ALLIED’s biodegradable detergent washing process replaces harsh industrial chemicals.

- Full-value recovery: When its journey ends, the jacket doesn’t. Down, shell, and thread separate cleanly and return to the loop. Down maintains loft for reuse; PERTEX | NetPlus® nylon re-enters fiber streams to create new NetPlus.

- Circularity, verified: The Helium Loop is being developed alongside the upcoming Circular Design Standard CDS V6.0 by circular.fashion, which is expected to launch in Q1 2026. The revised standard introduces a validation pathway for products designed either for open recycling systems or for partner-led innovative recycling systems. Peak Performance is working towards achieving certification for the Helium Loop under CDS V6.0, setting a new benchmark for complex outdoor products.

Speaking about the project, designer Marie Andersson commented, “The core insight is that true circularity isn’t about accepting compromises – it’s about engineering garments to be unmade as thoughtfully as they’re made. Our R&D Helium Loop proves that when premium materials meet thoughtful disassembly design with end-of-life in mind, circularity becomes a performance advantage as every component maintains its highest value across multiple lifecycles.”

David Stover, CEO of Bureo, the company behind NetPlus, added, “We enjoyed working collaboratively across different tiers of the supply chain to bring this project together for Peak Performance—connecting their thoughtful product design with traceable raw materials and innovative construction. The system to collect end-of-life garments is still very much in infancy, but initiating changes to design to prepare for the transition is a worthwhile challenge that was explored through this project.”

The Helium R&D Helium Loop Anorak marks another step in the brand’s long-term commitment to total range circularity by 2030, and will be publishing its pathway and milestones in Fall/Winter 2026, to make waste the last resort.

About Peak Performance

Born in the Swedish mountains out of a love for skiing in remote, untouched terrain, our passion for adventure and nature runs deep. Our purpose is simple: we bring the freeride spirit to the world. As for our products, they all have the same purpose – empowering the freedom to be adventurous and follow your own line. Whether it be on skis, by bike, or on foot, they offer a perfect balance of style and performance. Our Scandinavian heritage is ever present and our commitment to doing better things in a better way is our never-ending responsibility.

About NetPlus®

We’re a global collective of fishing communities, engineers, and environmentalists working to prevent fishing net pollution before it happens. We collect fishing nets at the end of their life, break them down to their raw molecules, and reform them into good-as-new nylon. Ready to restart life as products by forward-thinking brands. We’ve built a new kind of supply chain–one that’s reliable, transparent, and scalable. With responsibility woven in from sea to stitch. Learn more at netplus.co

About Resortecs

Resortecs offers pre- and post-consumer textile waste management services for the fashion, workwear, bedding and automotive industry. The company offers heat-dissolvable stitching threads (Smart Stitch™) and thermal disassembly systems (Smart Disassembly™) that enable easy, automated textile recycling on an industrial scale. Resortecs’ mission is to lead the textile industry towards full circularity by facilitating Design-for-Disassembly (DFD).

About ALLIED Feather + Down

Founded in Vernon, Calif. in 1987, ALLIED has been responsibly sourcing and sustainably processing down while simultaneously driving innovation within the insulation market for over 30 years. The family owned and operated business has earned the reputation as the largest, most reliable and most responsible supplier of raw material in the industry. Through the creation of programs such as the Responsible Down Standard (RDS) and TrackMyDown, ALLIED is committed to safeguarding the welfare of animals while protecting the environment. ALLIED remains a family owned company with facilities worldwide and is proud to produce the highest quality down technologies demanded by the most discerning brands in the outdoor, hospitality and fashion marketplaces. To learn more about ALLIED, please visit www.alliedfeather.com.